The promise “If you build it, they will come” may work in the movies, but it doesn’t get you very far in the military, where a ship, plane or tank has limited value without people who have the expertise to operate it, adapt it, maintain it, and sustain it. In the world of unmanned underwater vehicles (UUV), Peraton fills many critical enablement roles.

Peraton’s employees are a crucial link in the process from invention to implementation. Without Peraton employees testing and evaluating technology, then reporting the best techniques, tactics, and procedures (TTP) for use, these UUVs would not serve the military in their missions.

The Peraton UUV team’s greatest asset is their knowledge, skills, and ability. With extensive training as part of Peraton’s career progression framework, along with a mandatory overseas operational deployment, the Peraton team has a complete understanding of what customers want. Quickly grasping new concepts, Peraton employees also know what needs to be done to meet the customers’ end goals.

There is more than one path to field technology, depending on whether that equipment can be upgraded from a Commercial Off the Shelf (COTS) model or a Modified Off the Shelf (MOTS) model.

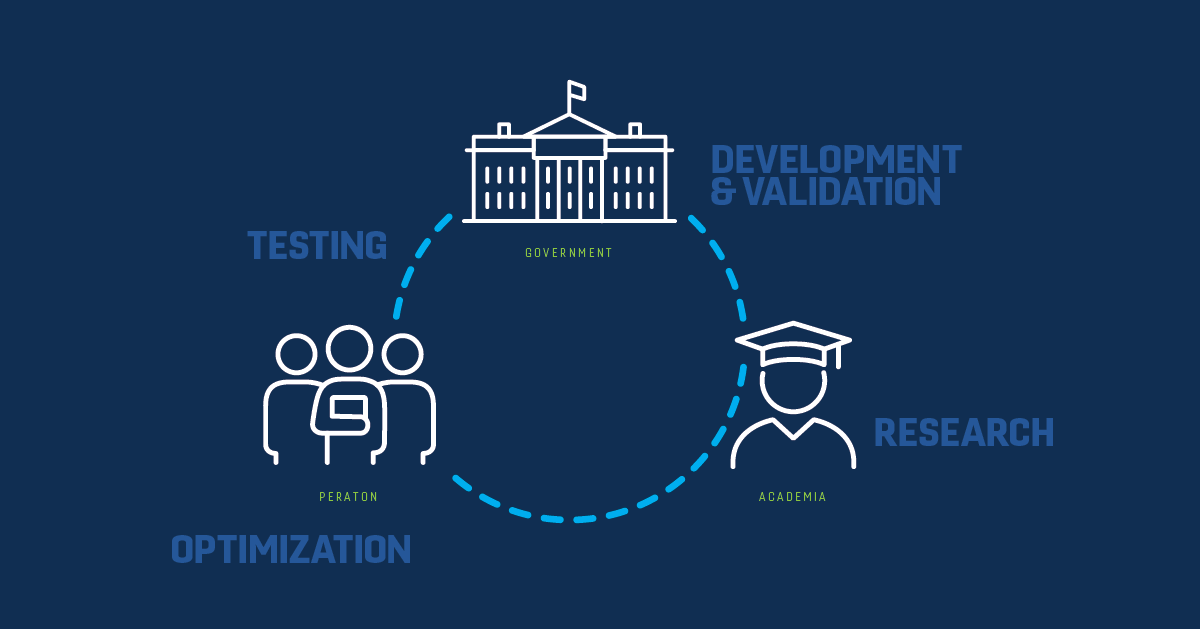

When it comes to UUVs, Peraton is there at every step of the unmanned technology process. There are three major stakeholders in the iterative and collaborative approach. Applied research laboratories (ARL) in academia create the technologies, the Department of Defense funds their development and validates their capabilities, and Peraton optimizes the equipment—informed by the company’s extensive experience and track record supporting real-world fleet operations.

For example, Peraton works on advanced sonar technology to enable the U.S. Navy to have greater image resolution at range. Pennsylvania State University makes the Small Synthetic Aperture Module (SSAM) and University of Texas at Austin makes the Autonomous Topographic Large Area Survey (ATLAS) vehicle. These tools give the Navy more certainty on what is or is not a target and allow for a much greater area to be surveyed.

“It’s a game changer for identification,” said Chris M., Peraton’s Director for Unmanned Systems. “The modules we’re refining will increase the accuracy of reporting, whether that’s environmental sensor data like salinity or search patterns for underwater mines.”

“In a mine countermeasure scenario, time is money and if we can get computer algorithms to help speed up that process, that can be incredibly valuable,” added Matt C., UUV Project Manager for Maritime Mission Support.

The government customer receives technology prototypes from the Office of Naval Research and the Peraton operations team execute test protocols to verify system capability. If a viability check meets the threshold requirements, then the instruments are shipped to an engineering testing and evaluation site for “stress tests.” After two years of pushing the tech to its limitations and making tweaks, it is ready for fleet introduction, a greater level of rigorous testing that is performed on site by fleet operators.

In order to deliver a product to fleet customers that can be used successfully in missions on day one, Peraton employees step into customers’ shoes to use the product and iron out potential kinks. Deployed overseas as “surrogate operators,” Peraton employees get into the customer’s mindset, seeing the instruments and their hardware and software all through the lens of a military operator.

Delivering the perfect UUV technology to Peraton’s customers is an iterative process

Delivering the perfect UUV technology to Peraton’s customers is an iterative process

“Our people are the best test pilots,” said Matt C. “Once we take them into the operational environment for product improvement, their feedback is relayed back to the lab for the next generation improvement.” The Peraton operators give recommendations for how best to use the equipment, suggesting small additions and adaptations specific to customer needs. The academic laboratories then improve the technology to fit the TTPs Peraton has developed. Once this step has been completed, the instruments are ready to be delivered. Due to the rigor of testing, the fleet receives products that are mission-designed and tailored for their defensive requirements.

“Compared to competitor fleet systems, we are much faster and nimbler,” said Chris M. “Also, given how much experience we all have in maritime settings, we not only train the military on the best way to use UUV tech, but we even teach those who made the products how to use them.”

After installation, Peraton fleet support representatives provide operational support by embedding in the fleet. These fleet support representatives can repair equipment on scene if damaged, getting it back in the water quickly. It is a rare occurrence for contractors to be able to perform repairs as soon as a malfunction occurs. Additionally, Peraton operators perform through post-mission analysis to ensure the equipment is always performing at its best.

The Peraton UUV team always goes above and beyond for the customer. Ready at a moment’s notice with employees internationally, the team is passionate about helping missions in both peacetime and in theater. This has helped Peraton become one of the nation’s most successful companies working in the unmanned maritime domain, and has set the stage for the company to compete for task orders as one of the participants in the U.S. Navy’s new unmanned surface vehicle (USV) IDIQ.

“Our people are our tools,” said Chris M., “selling expertise and customer service, helping deliver true capability to the fleets, and supporting real world operations.”